GERBER-WYSS

DIAGRAM APPLICATION

Have you ever faild the hardness of a standard hardening and tempering process, even though you have verified all the variables (hardening temperature, control of the atmosphere, type of material, etc) and for a request of 470 HB, obtain after hardening a hardness that does not even reach 400 HB?

Have you ever bought a certified material of the highest quality and fail to obtain the desired mechanical properties after heat treatment?

The characteristics are the same type of workpiece (same section 45 mm) produced with two different materials, 56Si7 (casting N has 1 and casting N 2) and 56SiCr7 (casting N 3). We preferred to perform the test in the same furnace load in order to avoid variations in the process conditions

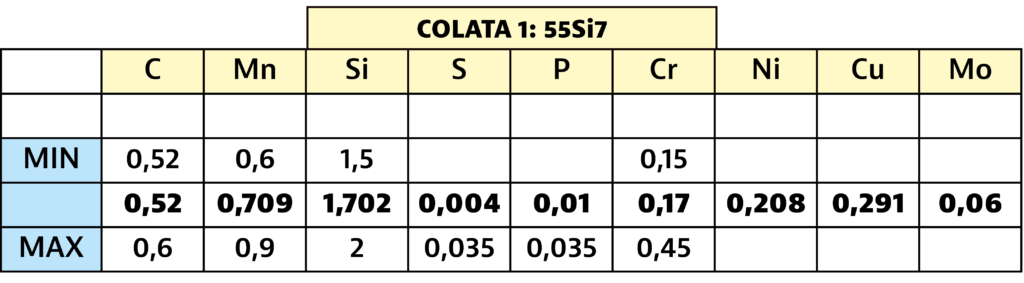

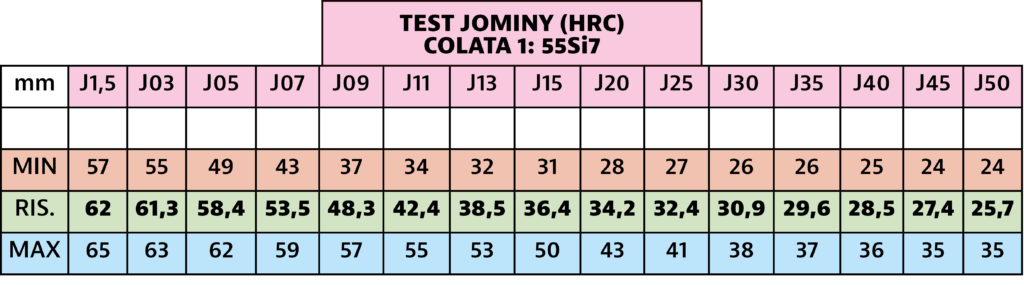

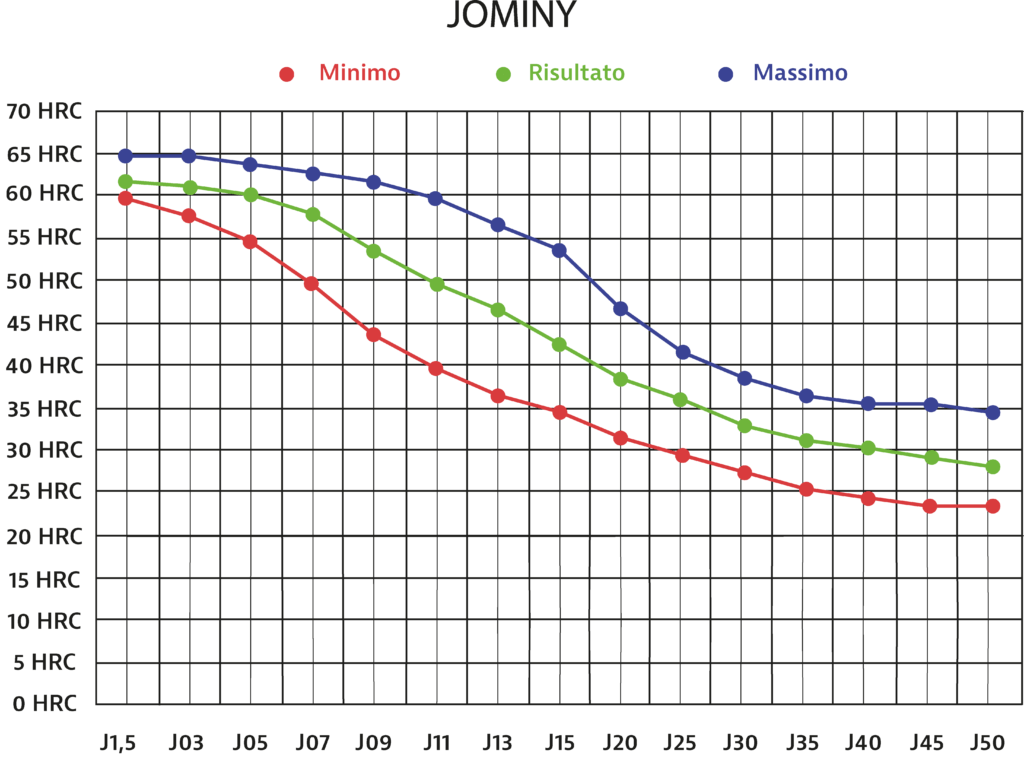

Casting 1: 55Si7

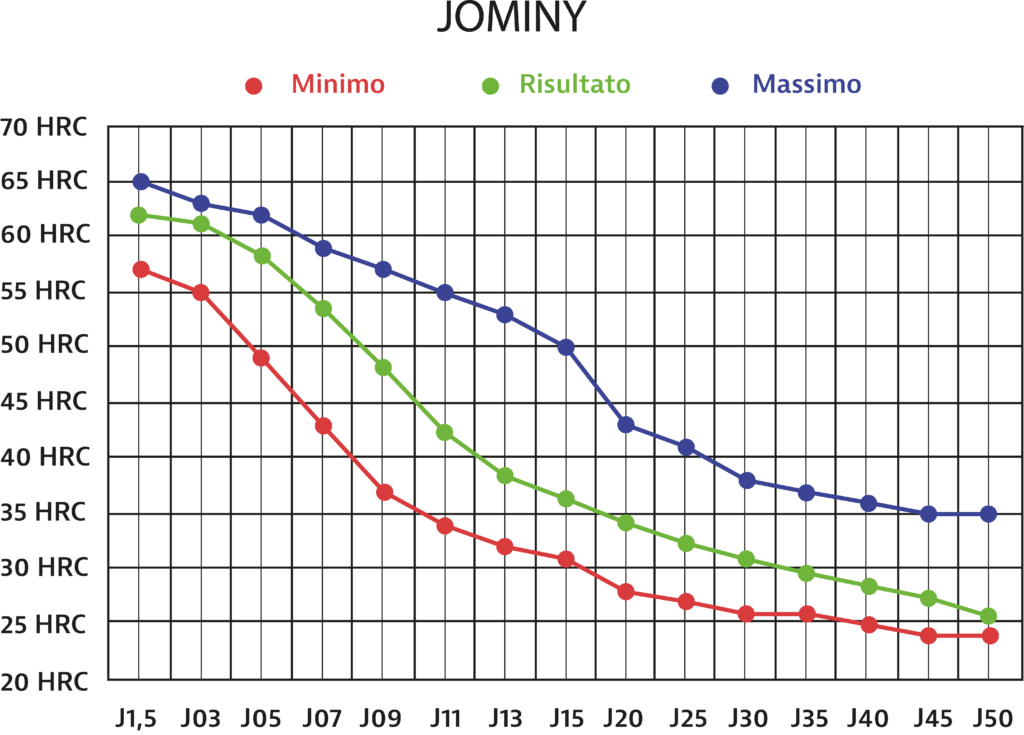

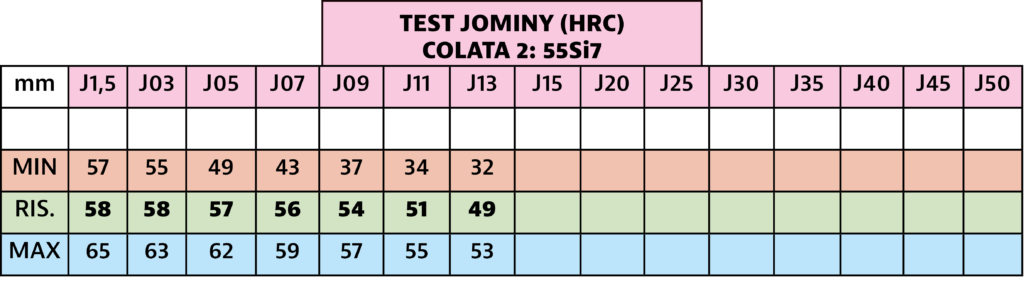

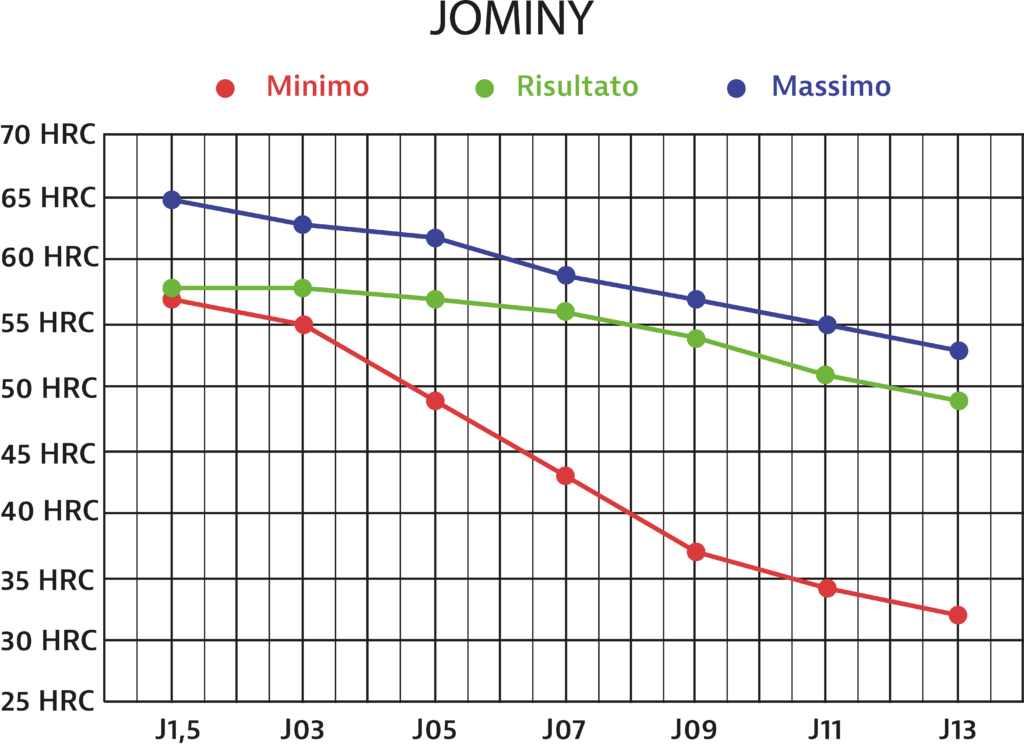

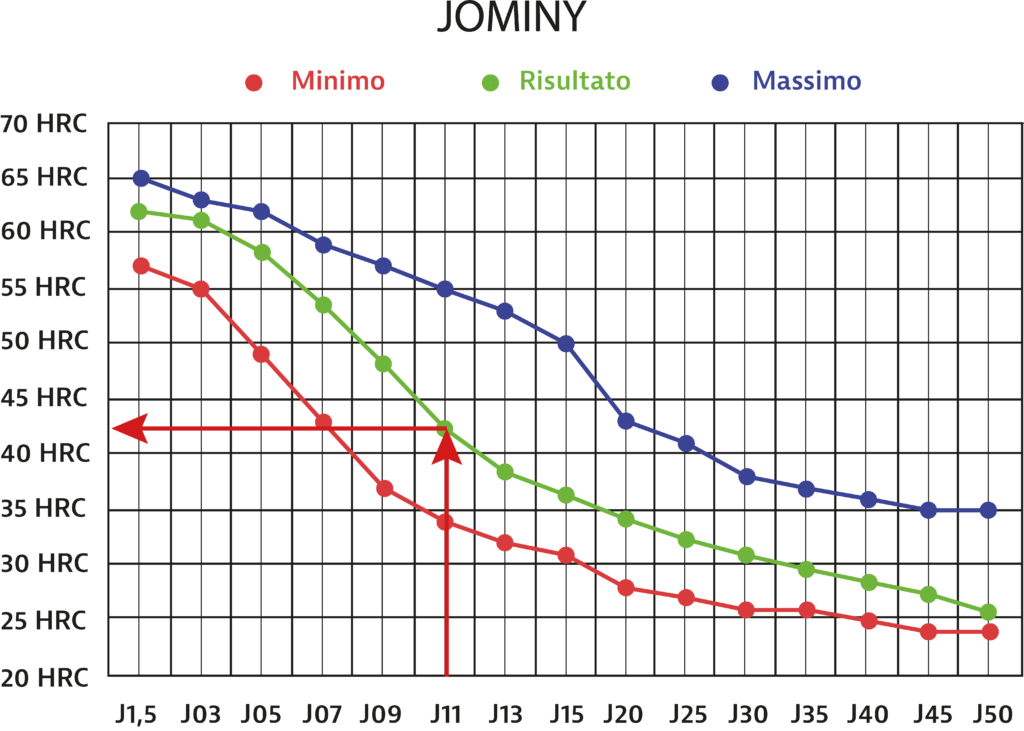

Casting 2: 55Si7

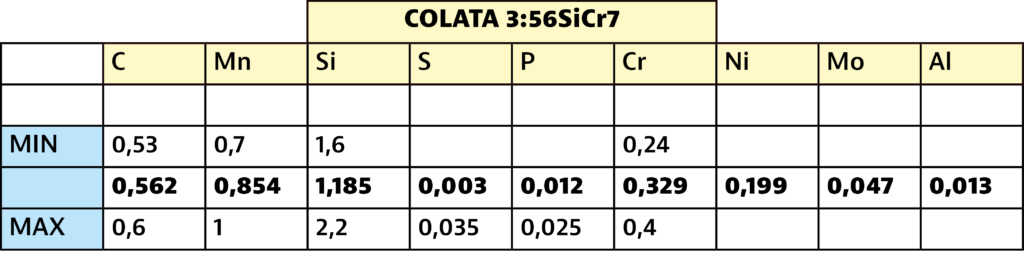

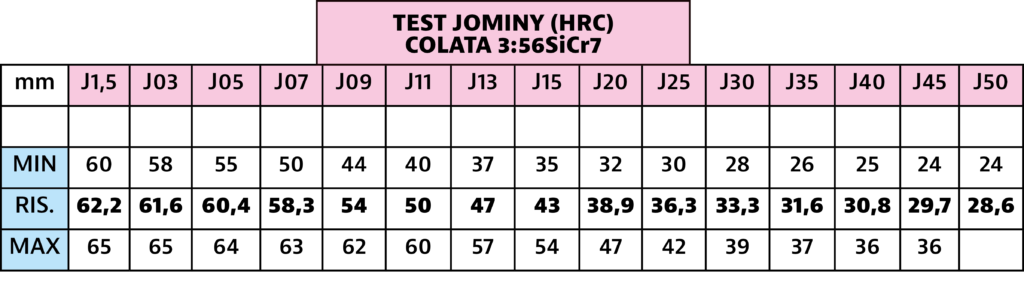

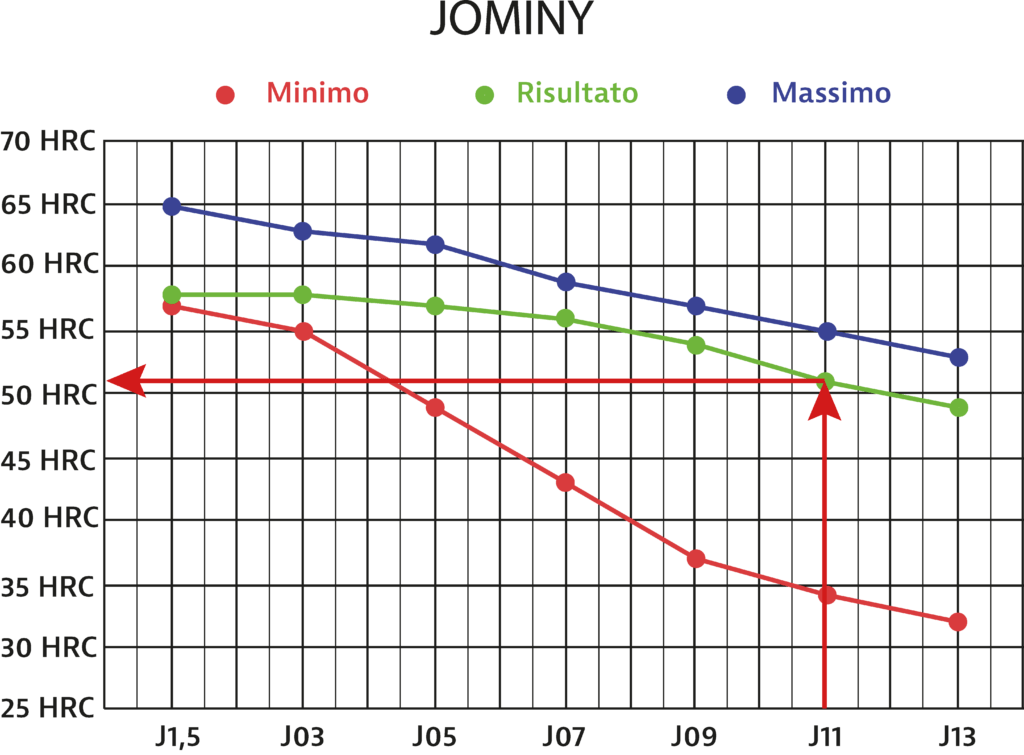

Casting 3: 56SiCr7

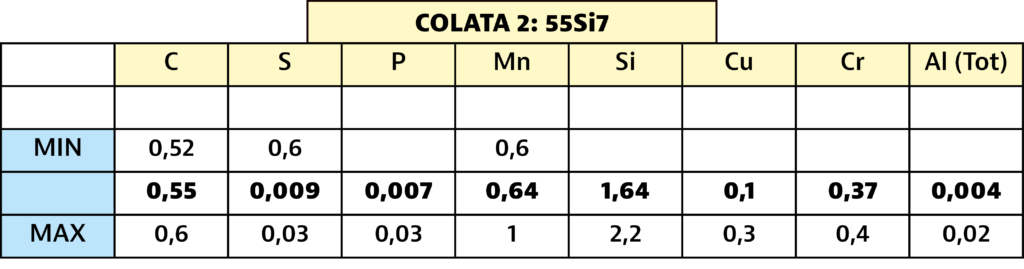

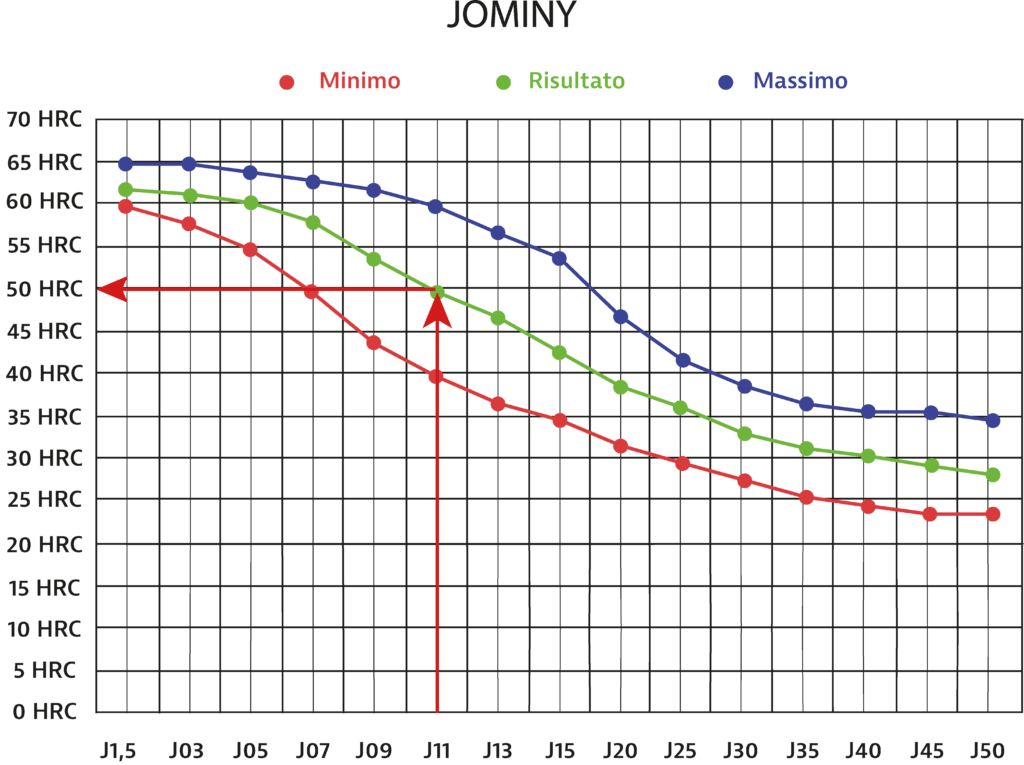

As can be seen from the chemical analyses of the different castings, the percentages of alloying elements and the corresponding Jominy curves fall within the established parameters as minimum and maximum.

This should reassure the customer who buys a lot of material to produce large-scale pieces. Surprise! Results after hardening:

Casting 1: 55Si7 = HB 352-415 EQUAL TO 121 e 143 Kg/mm2 (BELOW THE REQUEST OF 460 – 490 HB) NO

Casting 2: 55Si7 = HB 555 EQUAL TO 197 kg/mm2 (ABOVE THE REQUEST OF 460 – 490 HB ) OK

Casting 3: 56SiCr7 = HB 514 EQUAL TO 181 Kg/mm2 (ABOVE THE REQUEST OF 460 – 490 HB ) OK

Castings 2 and 3 meets the demand instead casting 1 remains below the request before tempering… but could such a result be expected?

Introduction to the Grossman’s work, curves of Lamont and the Diagrama Gerber-Wyss

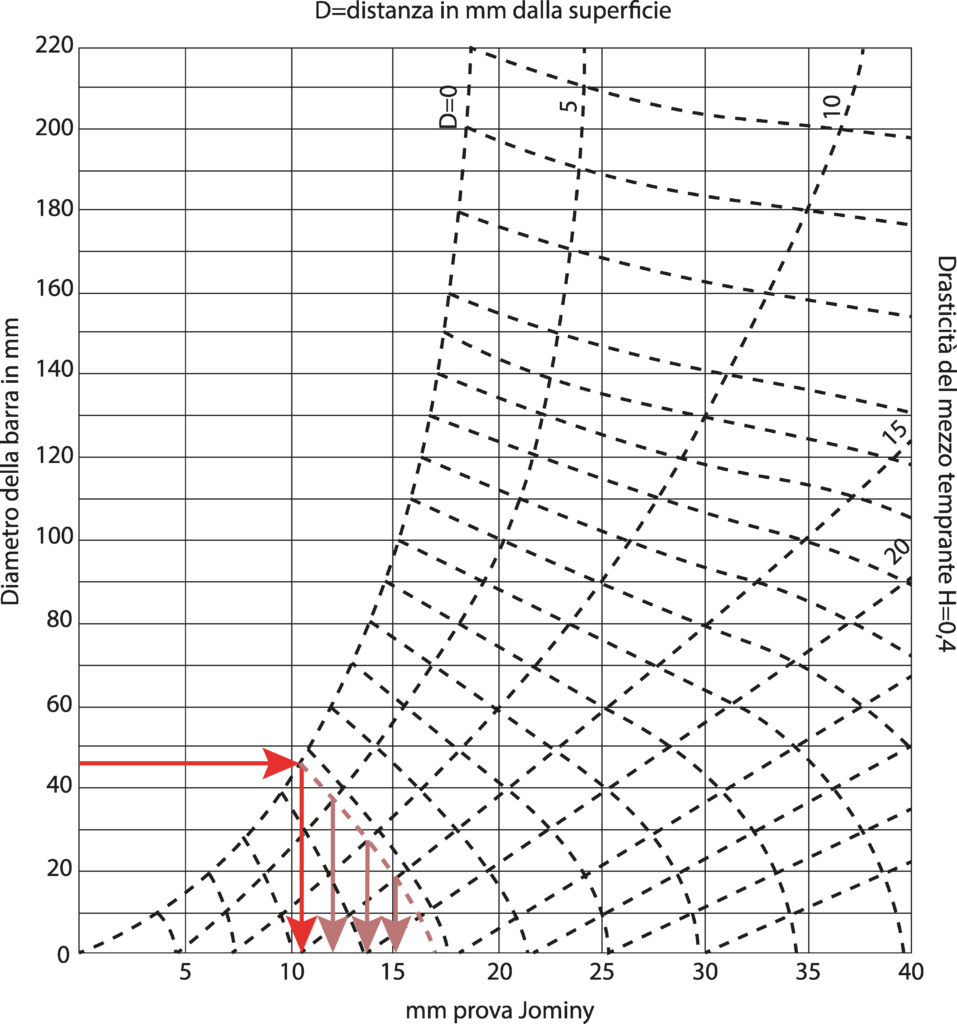

Simplifying things a lot, the “translation” of the Jominy temprability test is a fundamental process. There is a relationship between two points in a bar of the same material where the cooling rate expressed in °C/sec is assumed to be the same. This relationship is important for comparing the cooling rate of the Jominy sample to a depth Ji, with the cooling rate of a bar with a diameter X at a depth Y. This same speed results in the same transformation structure or one % of transformed martensite equal in both samples, or the same hardness HRC. In this way we can anticipate what hardness will reach a cylinder for example 45 mm diameter tempered in oil at 70 guessingC (taking simplified H=0.4 inches -1 for an oil of average drasticity) through the diagram of Gerber Wyss. This diagram is used to draw the curve in U (variation of hardness on the section) of a cylinder of defined diameter: on the axis of the ordinates we read the diameter of our cylinder, we trace a parallel to the ascisse until we meet the dotted line, at the cylinder surface. Here you follow the nearest continuous line and every time it crosses the dotted line (points of the U curve of our cylinder) you look for the intersection with the axis of the excise. Each point of the abscissa is the corresponding point of Jominy toughness.

Let’s apply the theory to our samples:

Casting 1

In correspondence with the Jominy test of Casting number 1:

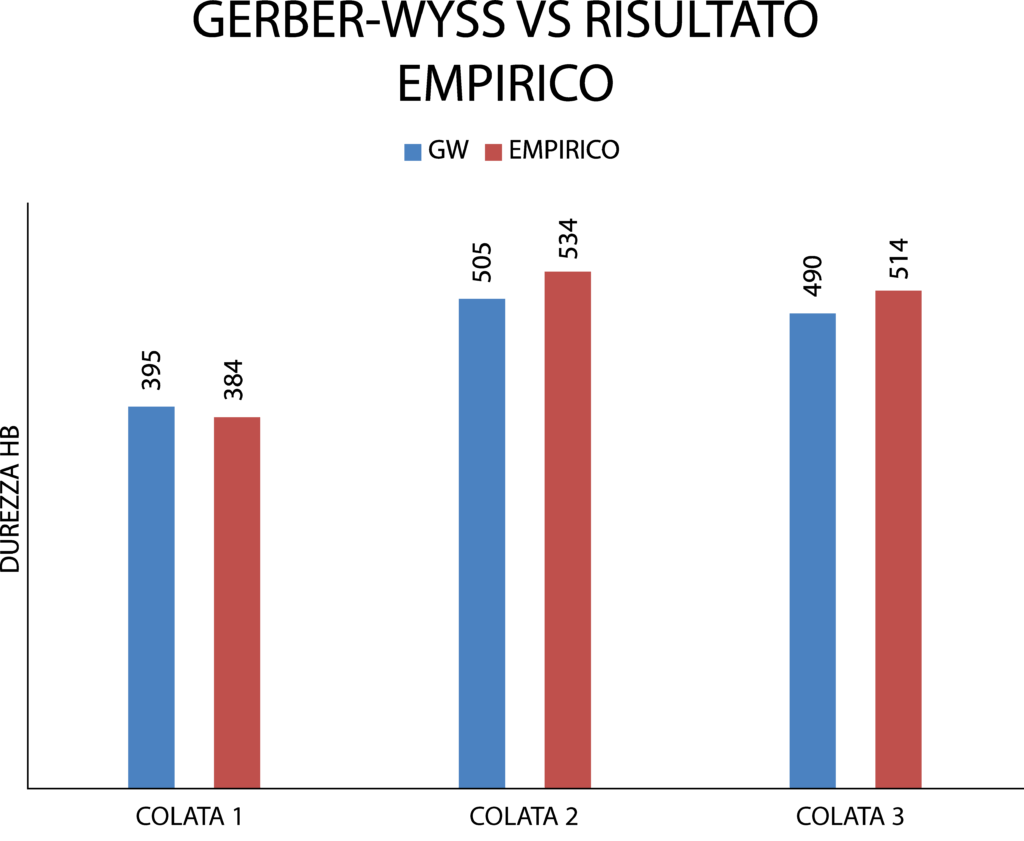

THEORETICAL: Hardness value at distance 13 mm of the sample Jominy = 42.5 HRC equal to 395 HB on our round diameter 45 mm

PRACTICAL: After hardening: Casting 1: 55Si7 = HB 352-415 EQUAL TO 121 and 143 Kg/mm2

Similarly, we analyse the theoretical results using the Geber-Wyss diagram for castings 2 or 3

Casting 2

THEORETICAL: Surface hardness value 51 HRC equal 505 HB

PRACTICAL: After hardening Casting 2: 55Si7 = HB 534 EQUAL to 189 kg/mm2

Casting 3

THEORETICAL: Surface hardness value around 50 HRC equal to 490 HB.

PRACTICAL: After Hardening Casting 3: 56SiCr7 = HB 514 EQUAL TO 181 Kg/mm2

Conclusion:

The data obtained from the empirical tests find a result not exact, but similar and proportional to those theorized by the Gerber-Wyss curves.

This analysis is essential to be able to purchase the material with awareness: the customer with the certificate of a casting can evaluate the achievable result after treatment, to avoid unpleasant surprises such as in the case of casting 1.

Bibliografiy:

[1] I criteri di scelta e di trattamento degli acciai da costruzione e da utensili Volume 1 – metallurgia di base – Cibaldi Dr. Cesare

[2] ASM Metals HandBook Volume 04 – Heat Treating

[3] http://www.vfioraso.it/4anno/aula_digitale/pagine_htm/data/1/curve_u.pdf